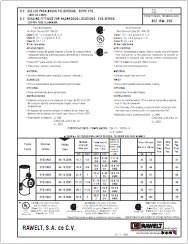

SEALING FITTINGS FOR HAZARDOUS LOCATIONS.

COPPER FREE ALUMINUM

EYS SERIES

- For dimensions:

See Spec Sheet R007-RW-321Class I, Div. 1 & 2, group A, B, C, D.

Class II, Div. 1 & 2, group E, F, G.

Class lll, Div. 1 & 2. - • Explosionproof

- • Dust-ignitionproof

- • Raintight

- • Wet locations

- For dimensions:

APPLICATIONS:

- Restrict the passage of gases, vapors, liquids, dust and flames from one portion of the electrical installation to another at atmospheric pressure and normal ambient temperatures.

- Saline chamber test to paint according to ASTM B117.

- Paint adhesion test according to ASTM 3359.

- Resistence to mechanicals impacts to body according to IK09, thanks to its design that does not have elements susceptible to breakage.

- NPT threaded for use with RIGID conduit.

- Vertical and Horizontal positions.

- 25% fill conduit

MATERIAL:

- Diecast copper free aluminum

FINISH:

- Electrostatic powder epoxy/polyester polymerized coating. Minimum thickness 2 mils.

OPTIONAL:

- Galvanized steel removable Nipple

INSTRUCTIONS:

- Are to be installed within 18″ of a device that produce sparks, arcs or high temperature.

- The thickness of the sealing compound shall not be less than the trade size of conduit and in no case less than 5/8″.

- Manufactured in compliance with:

- UL 886, UL 1203.

- CAN/CSA-C22.2 No. 30